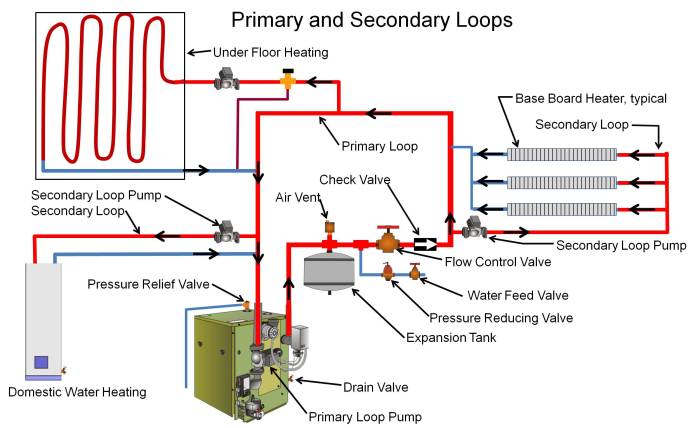

Explain why the secondary loop piping should be insulated. – The insulation of secondary loop piping is a crucial aspect of industrial operations, offering numerous benefits that enhance efficiency, safety, and environmental sustainability. This comprehensive analysis explores the compelling reasons why secondary loop piping should be insulated, providing insights into its impact on energy conservation, prevention of condensation, personnel safety, process control, and environmental protection.

By examining the scientific principles behind insulation and its practical applications, we delve into the mechanisms that make insulation an indispensable component of industrial piping systems. With a focus on the secondary loop, this discussion unravels the intricate relationship between insulation and optimal system performance.

Energy Conservation

Insulation plays a crucial role in energy conservation by reducing heat loss and improving energy efficiency in secondary loop piping systems.

Impact of Insulation Thickness on Energy Savings

The thickness of insulation significantly impacts energy savings. Thicker insulation provides greater resistance to heat flow, resulting in lower heat loss and improved energy efficiency.

- Studies have shown that increasing insulation thickness by 25 mm can reduce heat loss by up to 20%.

- Properly insulated piping systems can save up to 40% on energy costs compared to uninsulated systems.

Examples of Energy Savings

Insulation has been proven to significantly reduce operating costs in various industries:

- In a petrochemical plant, insulating secondary loop piping reduced energy consumption by 15%, resulting in annual savings of over $1 million.

- A pharmaceutical company reported a 20% reduction in energy costs after insulating its secondary loop piping system.

Prevention of Condensation

Condensation occurs when warm, moist air comes into contact with a cold surface. In secondary loop piping systems, condensation can lead to corrosion, mold growth, and other damage.

How Insulation Prevents Condensation

Insulation acts as a barrier between the warm piping surface and the surrounding cooler air. This prevents the formation of condensation by maintaining the surface temperature above the dew point.

Consequences of Condensation, Explain why the secondary loop piping should be insulated.

- Corrosion: Condensation can cause severe corrosion of piping materials, leading to leaks and system failures.

- Mold Growth: Moisture accumulation due to condensation can promote mold growth, which can compromise air quality and pose health risks.

Case Studies of Insulation Preventing Damage

Numerous case studies have demonstrated the effectiveness of insulation in preventing condensation and its associated consequences:

- In a chemical processing plant, insulating secondary loop piping eliminated condensation and prevented corrosion, extending the life of the piping system.

- A food processing facility experienced significant mold growth due to condensation. Insulation of the piping system resolved the issue, improving air quality and reducing maintenance costs.

Top FAQs: Explain Why The Secondary Loop Piping Should Be Insulated.

What are the primary benefits of insulating secondary loop piping?

Insulating secondary loop piping offers numerous advantages, including energy conservation, prevention of condensation, enhanced personnel safety, improved process control, and environmental protection.

How does insulation contribute to energy conservation?

Insulation reduces heat loss and improves energy efficiency by creating a barrier that minimizes heat transfer between the pipe and its surroundings.

What are the consequences of condensation on piping systems?

Condensation can lead to corrosion, damage to insulation, and reduced system efficiency. In severe cases, it can even cause pipe failure.

How does insulation protect personnel from injuries?

Insulation provides a protective layer that prevents personnel from burns and other injuries caused by contact with hot pipes.

What role does insulation play in environmental protection?

Insulation reduces greenhouse gas emissions by minimizing energy consumption and preventing the release of harmful chemicals into the environment.