NEC 110.26 Dedicated Equipment Space: A Comprehensive Guide to Electrical Safety

The National Electrical Code (NEC) establishes critical safety standards for electrical installations, and NEC 110.26 specifically addresses dedicated equipment spaces. Understanding these requirements is essential for ensuring the safety and functionality of electrical systems in various settings.

NEC 110.26 Dedicated Equipment Space Requirements

NEC 110.26 provides regulations for dedicated equipment spaces, which are essential for the safe and efficient operation of electrical equipment. These spaces are designed to house electrical equipment and provide adequate access for maintenance and repair.

Purpose and Scope

The purpose of NEC 110.26 is to ensure that dedicated equipment spaces are properly designed and constructed to meet the specific needs of the equipment they house. This includes providing adequate space for equipment installation, maintenance, and repair, as well as protection from environmental hazards such as fire, water, and dust.

Examples of Dedicated Equipment Spaces

Dedicated equipment spaces can be found in a variety of settings, including:

- Electrical closets

- Mechanical rooms

- Pump rooms

- Control rooms

Minimum Dimensions and Clearances

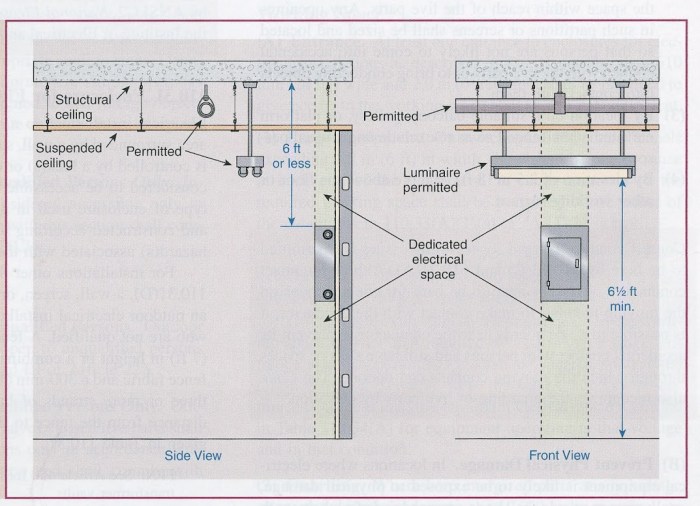

NEC 110.26 specifies minimum dimensions and clearances for dedicated equipment spaces based on the size and type of equipment being housed. These requirements ensure that there is sufficient space for equipment installation, maintenance, and repair, as well as adequate access for personnel.

The minimum dimensions for dedicated equipment spaces are as follows:

- Width: 24 inches (610 mm)

- Depth: 30 inches (762 mm)

- Height: 6 feet 6 inches (1.98 m)

In addition to the minimum dimensions, NEC 110.26 also specifies minimum clearances around equipment. These clearances are necessary to provide adequate access for personnel and to prevent the spread of fire or other hazards.

The minimum clearances around equipment are as follows:

- Front: 3 feet (914 mm)

- Sides: 2 feet (610 mm)

- Rear: 3 feet (914 mm)

Types of Equipment that Can Be Installed in Dedicated Equipment Spaces

Dedicated equipment spaces are specifically designed to house electrical equipment, providing a safe and organized environment for its operation and maintenance. The types of equipment that can be installed in these spaces vary depending on the specific requirements of the installation.

This section will identify the types of electrical equipment that can be installed in dedicated equipment spaces, explain the requirements for installing different types of equipment, and provide examples of equipment that can and cannot be installed in these spaces.

Equipment Types

The types of electrical equipment that can be installed in dedicated equipment spaces include:

- Electrical panels and switchboards:These are the main distribution points for electrical power in a building, and they contain circuit breakers or fuses to protect the circuits from overloads and short circuits.

- Transformers:These are used to change the voltage of electrical power, and they can be either step-up or step-down transformers.

- Generators:These are used to provide backup power in the event of a power outage.

- Uninterruptible power supplies (UPSs):These are used to provide continuous power to critical equipment in the event of a power outage.

- Motor control centers (MCCs):These are used to control the operation of motors, and they contain circuit breakers or fuses to protect the motors from overloads and short circuits.

Installation Requirements

The installation of electrical equipment in dedicated equipment spaces must meet the requirements of the National Electrical Code (NEC) and any other applicable codes and standards. These requirements include:

- Adequate space:There must be sufficient space around the equipment for maintenance and repair.

- Ventilation:The space must be adequately ventilated to prevent the equipment from overheating.

- Access:The equipment must be easily accessible for maintenance and repair.

- Security:The space must be secure to prevent unauthorized access.

Examples

Examples of equipment that can be installed in dedicated equipment spaces include:

- Electrical panels

- Switchboards

- Transformers

- Generators

- UPSs

- MCCs

Examples of equipment that cannot be installed in dedicated equipment spaces include:

- Office equipment

- Storage equipment

- Flammable materials

- Corrosive materials

Ventilation and Cooling Requirements for Dedicated Equipment Spaces: Nec 110.26 Dedicated Equipment Space

Dedicated equipment spaces require adequate ventilation and cooling to prevent overheating and ensure the proper functioning of equipment. Inadequate ventilation can lead to equipment failure, reduced lifespan, and increased energy consumption.

There are several methods that can be used to provide adequate ventilation and cooling in dedicated equipment spaces, including:

- Natural Ventilation:Utilizing openings in the building envelope, such as windows, doors, and vents, to allow for the circulation of outside air.

- Mechanical Ventilation:Employing fans or blowers to circulate air within the space, either by exhausting stale air or introducing fresh air.

- Air Conditioning:Using a dedicated air conditioning system to control the temperature and humidity within the space.

Ventilation and Cooling Systems

Various ventilation and cooling systems can be used in dedicated equipment spaces, including:

- Packaged Rooftop Units (RTUs):Self-contained units that combine cooling, heating, ventilation, and air conditioning functions in a single package.

- Split Systems:Consisting of an outdoor unit that houses the compressor and condenser and an indoor unit that contains the evaporator and blower.

- Variable Air Volume (VAV) Systems:Regulate the airflow to individual zones within the space, allowing for efficient temperature control.

Accessibility and Safety Considerations for Dedicated Equipment Spaces

![]()

Dedicated equipment spaces require careful attention to accessibility and safety to ensure the proper operation and maintenance of the equipment they house. These spaces must be designed and maintained to provide adequate access for authorized personnel while mitigating potential safety hazards.

Requirements for Access to Dedicated Equipment Spaces

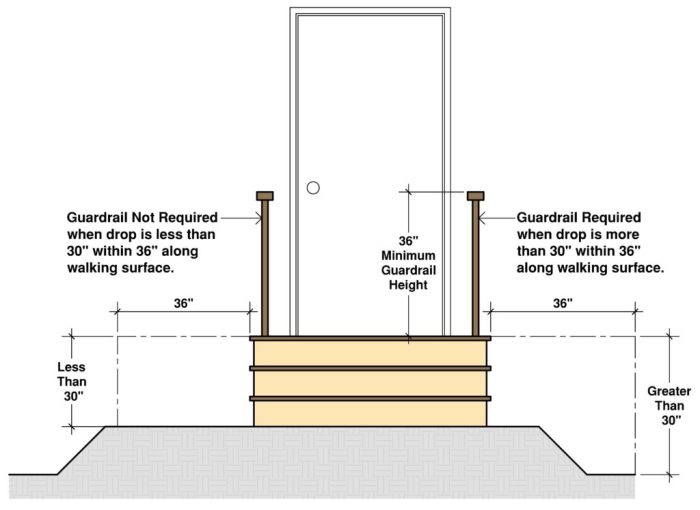

NEC 110.26(A) Artikels the requirements for providing access to dedicated equipment spaces. These spaces must be accessible without having to enter or pass through other occupied spaces, such as offices or storage areas. Additionally, the access path must be unobstructed, well-lit, and at least 30 inches wide.

A clear working space of at least 30 inches in front of all equipment must also be provided.

Safety Hazards in Dedicated Equipment Spaces, Nec 110.26 dedicated equipment space

Dedicated equipment spaces can present several safety hazards, including electrical hazards, fire hazards, and tripping hazards. Electrical hazards arise from the presence of high-voltage equipment, while fire hazards stem from the potential for electrical fires or the presence of flammable materials.

Tripping hazards can occur due to cables, cords, or other obstacles on the floor.

Mitigation of Safety Hazards in Dedicated Equipment Spaces

To mitigate these safety hazards, several measures can be implemented. Electrical hazards can be addressed through proper grounding, insulation, and bonding of equipment. Fire hazards can be minimized by using fire-resistant materials, installing smoke detectors and fire extinguishers, and maintaining proper housekeeping.

Tripping hazards can be eliminated by securing cables and cords and keeping the floor clear of obstructions.

Labeling and Identification Requirements for Dedicated Equipment Spaces

Dedicated equipment spaces require specific labeling and identification to ensure proper operation and maintenance. This includes labeling the equipment itself, as well as the space where it is located.

Labeling of Equipment

All equipment installed in a dedicated equipment space must be clearly labeled with the following information:

- Manufacturer’s name and model number

- Electrical rating (voltage, amperage, and wattage)

- Purpose of the equipment

- Any special operating instructions or precautions

Labeling of the Space

The dedicated equipment space itself must also be clearly labeled with the following information:

- Purpose of the space

- Location of the main electrical disconnect

- Location of the fire extinguisher

- Any other relevant safety information

Importance of Proper Labeling and Identification

Proper labeling and identification of dedicated equipment spaces is essential for the following reasons:

- Ensures that the equipment is operated and maintained correctly

- Helps to prevent accidents and injuries

- Facilitates troubleshooting and repairs

- Provides documentation for insurance purposes

Answers to Common Questions

What is the purpose of NEC 110.26?

NEC 110.26 establishes minimum requirements for dedicated equipment spaces to ensure the safety and accessibility of electrical equipment.

What types of equipment can be installed in dedicated equipment spaces?

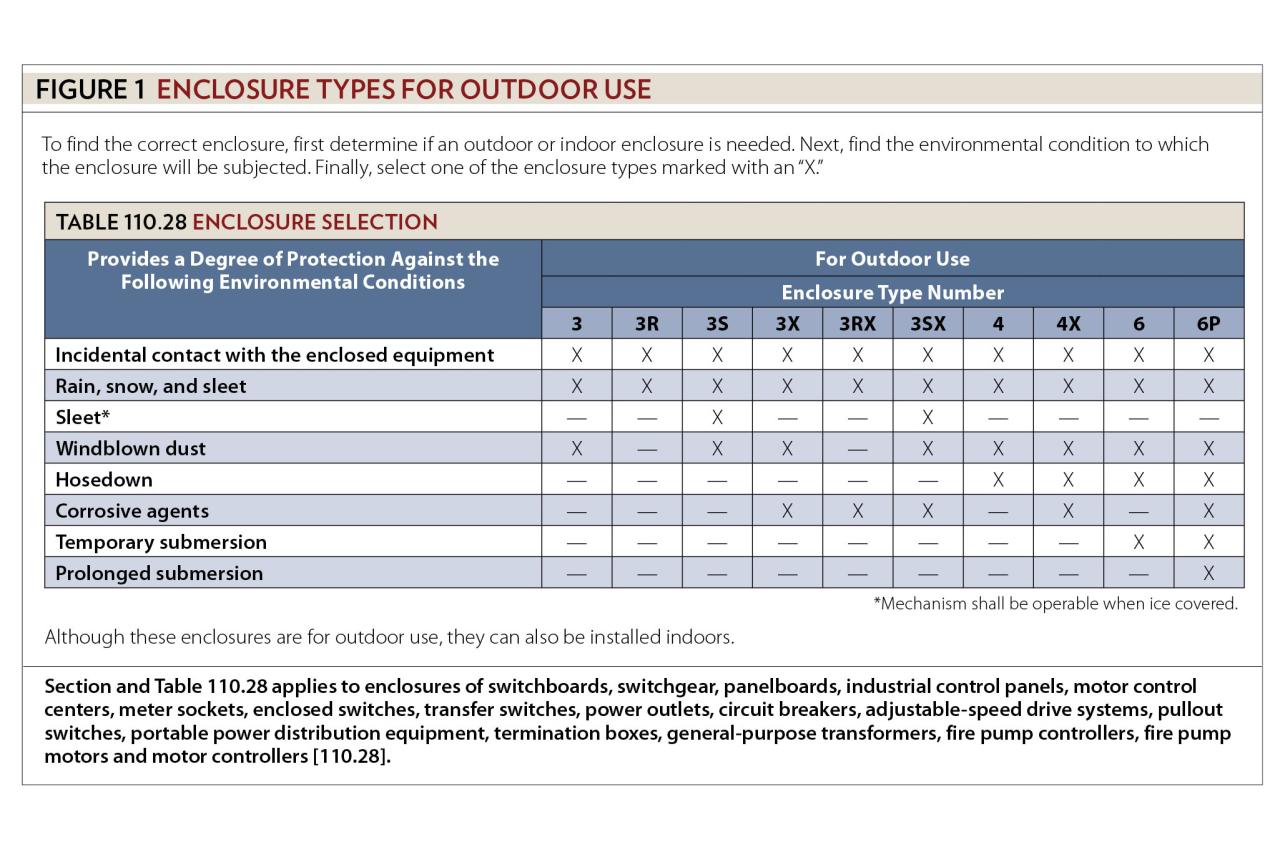

Dedicated equipment spaces can house electrical equipment such as transformers, switchboards, panelboards, and motor control centers.

What are the ventilation and cooling requirements for dedicated equipment spaces?

Dedicated equipment spaces must have adequate ventilation and cooling to prevent overheating and ensure proper equipment operation.